Unlocking the mysteries behind high pressure rotary valves

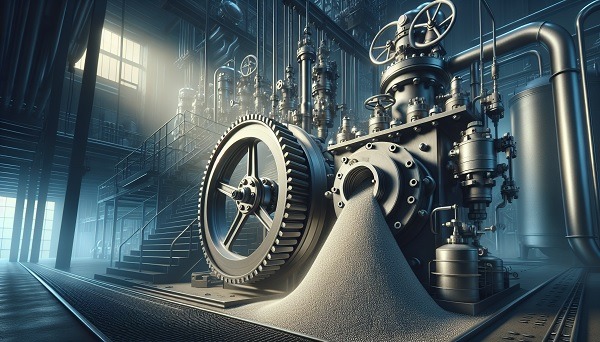

When we talk about keeping things moving, especially in the world of industrial processing, the spotlight often lands on a not-so-talked-about hero: the high pressure Rotary valves. This critical component, nestled within the complex machinery of bulk material handling, is a key player in ensuring a smooth, consistent flow of materials — from grains in a silo to powdered chemicals in pharmaceutical production. But what makes these valves so special, especially when they operate under high-pressure conditions?

Understanding the heartbeat of rotary valves in high-pressure scenarios

At its core, the idea behind a rotary valve is quite simple: it’s all about managing the flow of a material from one chamber to another while maintaining a tight seal against pressure or vacuum conditions. However, the simplicity ends there. When these valves function under high pressure, they need to be designed with precision to withstand the force, avoiding leaks that can lead to loss of materials or, worse, safety hazards. The designs involve using robust materials that can bear the brunt of the pressure, ensuring longevity and reliability. If you’ve ever wondered where High pressure plays a demanding role, rotary valves find a way to stand steadfast, proving to be crucial in a myriad of industries.

The indispensable role of high-pressure rotary valves in industries

It’s not just about moving things from point A to B; high pressure rotary valves ensure the process is efficient, reliable, and, above all, safe. In industries where materials are conveyed pneumatically, such as in the case of food grains or chemical powders, maintaining the integrity of the material is paramount. These valves make sure there’s no contamination or degradation of the product, ensuring that what goes in is exactly what comes out — just at a different location. From the precise delivery of ingredients in food processing to handling abrasive minerals in mining, the role of these valves cannot be overstated. Real-life applications span far and wide, demonstrating the ubiquitous need for reliable material handling solutions.

What the future holds: advancements and innovations

As with most industrial machinery, the journey of improvement never stops. High pressure rotary valves are no different, with ongoing advancements aimed at enhancing their efficiency, reliability, and environmental footprint. Innovations in materials technology mean that newer valves are not only stronger but also lighter and more compact, capable of handling greater pressures with ease. Moreover, the digital transformation sweeping across industries has not left these devices behind. Imagine valves equipped with sensors providing real-time data on performance parameters, enabling predictive maintenance, and reducing downtime. Such future advancements promise to keep these critical components at the forefront of industrial processing technologies.

So, the next time you enjoy a bar of chocolate, know that high pressure rotary valves played a part in its journey from cocoa to your taste buds — a testament to the silent but significant role they play in our daily lives. As we look forward, it’s exciting to imagine how further innovations will continue to push the boundaries of what these essential devices can achieve.